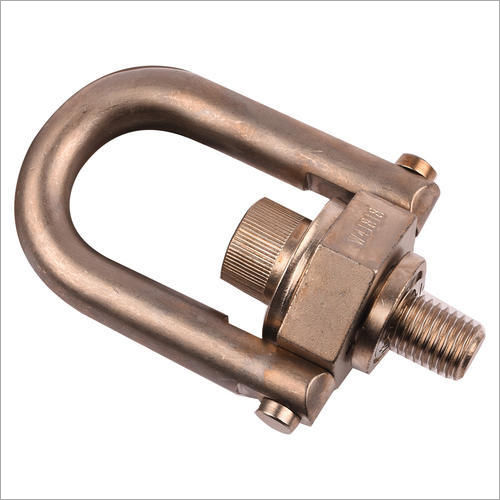

McMaster Shoulder Bolt

Price 990 INR/ Piece

McMaster Shoulder Bolt Specification

- Finish

- Polished

- Usage

- Industrial

- Material

- Steel

- Size

- Standard

- Color

- Black And Silver

McMaster Shoulder Bolt Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 2 Week

About McMaster Shoulder Bolt

MCmaster Shoulder Bolt is a standard shoulder screw of high functionality. This is a metric shoulder screw, which works as a shaft as well as axle for different moving parts and bearings. This is suited for the applications, which need smooth and accurate movement. MCmaster Shoulder Bolt has a head of special design, which maintain the place of rotating and sliding parts. It allows the users to use it as the alignment guides of extreme functionality. This is suited for outdoor as well as wash-down environments. It can work as the stripper bolt and shoulder bolt.

Product Specification

| Type of Bolts | Round-head |

| Shape | Circular |

| Surface Treatment | Black Oxide |

| Coating | Self |

| Material | Steel |

| Brand | McMaster |

| Finish | Polished |

Premium Steel Construction

Constructed with robust steel, this shoulder bolt ensures superior strength and durability for demanding industrial operations. Its resilience makes it suitable for repeated use in high-stress environments, providing long-lasting performance for various mechanical assemblies.

Polished Finish for Enhanced Protection

The polished finish not only elevates the bolts appearance with a sleek black and silver look but also offers enhanced protection against corrosion. This treatment maintains the bolts integrity and function under challenging industrial conditions, reducing maintenance requirements.

FAQs of McMaster Shoulder Bolt:

Q: How is the McMaster Shoulder Bolt typically used in industrial applications?

A: The McMaster Shoulder Bolt is widely used in industrial settings to provide precise alignment and secure fastening of moving components, such as pulleys and gears, in machinery. Its design allows controlled movement and reliable assembly in mechanical systems.Q: What are the benefits of choosing a polished steel shoulder bolt with black and silver colors?

A: Opting for a polished steel shoulder bolt provides enhanced corrosion resistance and an appealing aesthetic suitable for visible installations. The black and silver finish adds versatility, matching various equipment designs while ensuring durability.Q: When should I replace a shoulder bolt in my machinery equipment?

A: Shoulder bolts should be replaced when signs of excessive wear, deformation, or corrosion are evident, or if they no longer maintain tight alignment. Regular inspection during maintenance cycles helps prevent operational failures and ensures safety.Q: Where can I purchase McMaster Shoulder Bolts in India?

A: You can purchase McMaster Shoulder Bolts from authorized dealers, distributors, manufacturers, retailers, suppliers, traders, and wholesalers across India. Many suppliers offer bulk purchasing and delivery services for industrial customers.Q: What is the manufacturing process for a polished steel shoulder bolt?

A: Manufacturing involves precision machining of steel to exact dimensions, followed by surface finishing to achieve a polished look. The bolt is then colored black and silver using specialised treatments, ensuring both aesthetic appeal and enhanced durability.Q: How does using a standard size shoulder bolt benefit industrial assembly?

A: Standard size shoulder bolts facilitate uniform installation and replacement, reducing the risk of mismatched components. This helps streamline maintenance procedures and ensures consistent performance across equipment.Q: What precautions should be taken when using shoulder bolts in industrial environments?

A: Ensure proper torque during installation, periodically inspect bolts for wear or corrosion, and avoid using damaged fasteners. Choosing bolts with the appropriate finish and material for the environment improves lifespan and reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in McMaster Carr Product Category

Mcmaster-Carr And Grainger Tools

Price 5601 INR / Set

Minimum Order Quantity : 1 Set

Material : Alloy Steel

Surface Treatment : Other, Zinc Plated

Shape : Round

McMaster Carr Products

Price 1909 INR / Piece

Minimum Order Quantity : 1 , , Piece

Material : Stainless Steel

Surface Treatment : Other, Passivated

Shape : Cylindrical

McMaster Carr

Price 30000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Steel

Surface Treatment : Polishing

Size : Standard

McMaster Carr Bolt

Price 500 INR / Piece

Minimum Order Quantity : 1 , , Piece

Material : Stainless Steel

Surface Treatment : Powder Coated

Shape : Round

Size : Standard

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free