Flow Control Valves

Flow Control Valves Specification

- Structure

- Needle/Ball Type

- Material

- Stainless Steel

- Power

- Hydraulic

- Pressure

- 6 Bar

- Media

- Air

- Working Temperature

- -25C to +80C

- Port Size

- 1/4 to 2 BSP/NPT

- Surface

- Polished/Corrosion Resistant Coating

- Shape

- Cylindrical

- Application

- Industrial/Hydraulic Systems/Fluid Control

- Flow Rate

- Up to 150 L/min

- Operating Principle

- Direct Acting

- Connection Type

- Threaded/Female

- Leakage Rate

- < 0.05 ml/min at rated pressure

- Sealing Material

- NBR/Viton

- Body Finish

- Electroplated

- Weight

- From 0.5 kg to 4 kg

- Handle Material

- Aluminum/Plastic

- Control Type

- Adjustable Manual

Flow Control Valves Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 3-4 Days

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Africa, Central America, South America, Western Europe, Asia

- Main Domestic Market

- All India

About Flow Control Valves

Optimum quality stainless steel is being used in the production of this type of Flow Control Valves on a wide scale. Offered valves have mounting positions at both the ends, which enable them to perform efficiently. It requires 6 bar of pressure for keeping the essential processes variable, including temperature, pressure within operating range. As the name of the product Flow Control Valves, itself depicts its functioning that offered valves control the flowing of the fluids, such as liquids, gasses, chemical compounds etc. These can also be known as automatic control valves as they do not require any external power source.

Features of Flow Control Valves:

- These can be fitted into positioners and actuators

- These have mountings on both the ends

- These are available in customized forms

- At cost effective rates these can be availed

Product details

| Material | Stainless Steel |

| Media | Air |

| Mounting Position | Both ends |

| Type | Flow Control Valve |

| Pressure (Bar) | 6 |

| Color | Silver |

Robust Construction & Versatile Applications

Fabricated from corrosion-resistant stainless steel and finished with electroplating or polishing, these flow control valves are designed to endure demanding environments. Their needle or ball-type structure supports precise flow control for both industrial and hydraulic fluid management. With port sizes ranging from 1/4 to 2 BSP/NPT, they are well-suited to a wide variety of fluid control setups, supporting industries throughout India.

Superior Leak Protection and Reliable Performance

A direct-acting mechanism and carefully engineered NBR or Viton seals provide outstanding leak resistance (less than 0.05 ml/min at rated pressure), ensuring secure and stable operation. Rated for consistent performance up to 6 Bar and flow rates reaching 150 L/min, these valves are ideal for demanding usage in harsh industrial and hydraulic applications, offering reliability even in fluctuating temperature ranges.

FAQ's of Flow Control Valves:

Q: How do I install a threaded flow control valve in my hydraulic system?

A: To install the valve, ensure the system is depressurized. Choose the appropriate BSP or NPT port size, apply suitable thread sealant, and connect the valve to your pipeline with compatible female threads. Align it according to the designated flow direction, and tighten it securely. Finally, check for leaks once the system is pressurized.Q: What sealing materials are available, and how do I choose between NBR and Viton?

A: NBR (nitrile butadiene rubber) is recommended for general purpose and air applications within standard temperatures, whereas Viton offers superior chemical and temperature resistance if your application involves aggressive environments or higher temperatures up to +80C.Q: When should I use a direct acting flow control valve in my application?

A: Direct acting flow control valves are ideal when you require immediate response and precise manual adjustment. They are commonly used where rapid and dependable flow regulation is critical, such as in industrial or hydraulic systems demanding minimal leakage and consistent pressure control.Q: Where can I purchase these flow control valves in India?

A: These valves are widely available through authorized dealers, distributors, manufacturers, wholesalers, suppliers, and retailers throughout India. You can contact local or national suppliers specializing in industrial and hydraulic components for availability and technical support.Q: What benefits does the electroplated body finish provide?

A: Electroplating and polished finishes enhance corrosion resistance, extend the service lifespan, and maintain the aesthetic appeal of the valve. This protective coating shields the stainless steel body from harsh industrial conditions and frequent exposure to moisture or chemicals.Q: How do I adjust the flow rate using the manual control handle?

A: By turning the adjustable manual handle-made from either aluminum or plastic-you can fine-tune the valve opening to regulate flow precisely up to 150 L/min. Adjust clockwise to decrease flow and counterclockwise to increase, monitoring system response for optimal performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Valves Category

Festo Valve

Price 1800 INR / Piece

Minimum Order Quantity : 1 Piece

Shape : Rectangular

Application : Pneumatic Automation, Air Control

Port Size : G1/8 to G1/4

Surface : Other, Anodized or coated

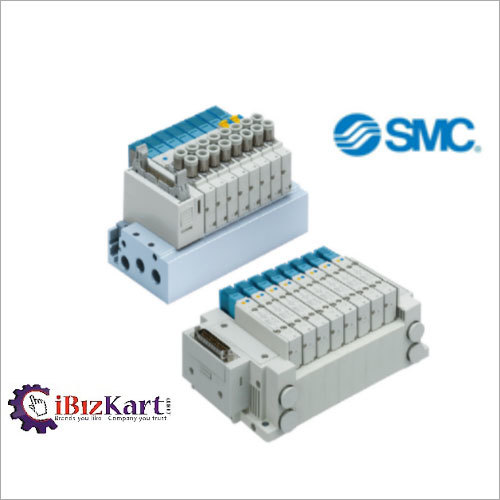

SMC Valve

Price 3900 INR

Minimum Order Quantity : 1 Piece

Shape : Rectangular

Application : Industrial Automation

Port Size : 1/4 inch

Surface : Other, Polished

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS